Production VSC

VSC 500

- Workpiece dia., max.: 500 mm | 19.5 in

- Workpiece length, max.: 200 mm | 8 in

- Chuck dia., max.: 500 mm | 19.5 in

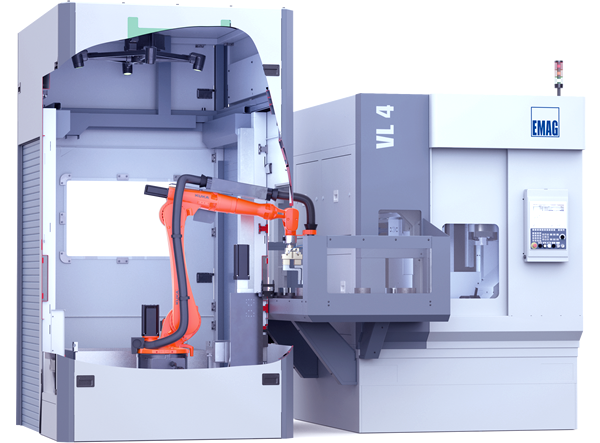

Automated Production Lathe for Heavy-Duty Machining

Where large, heavy workpieces have to be machined, the manual loading of horizontal lathes is very time-consuming and can also be very costly if loading gantries are used.

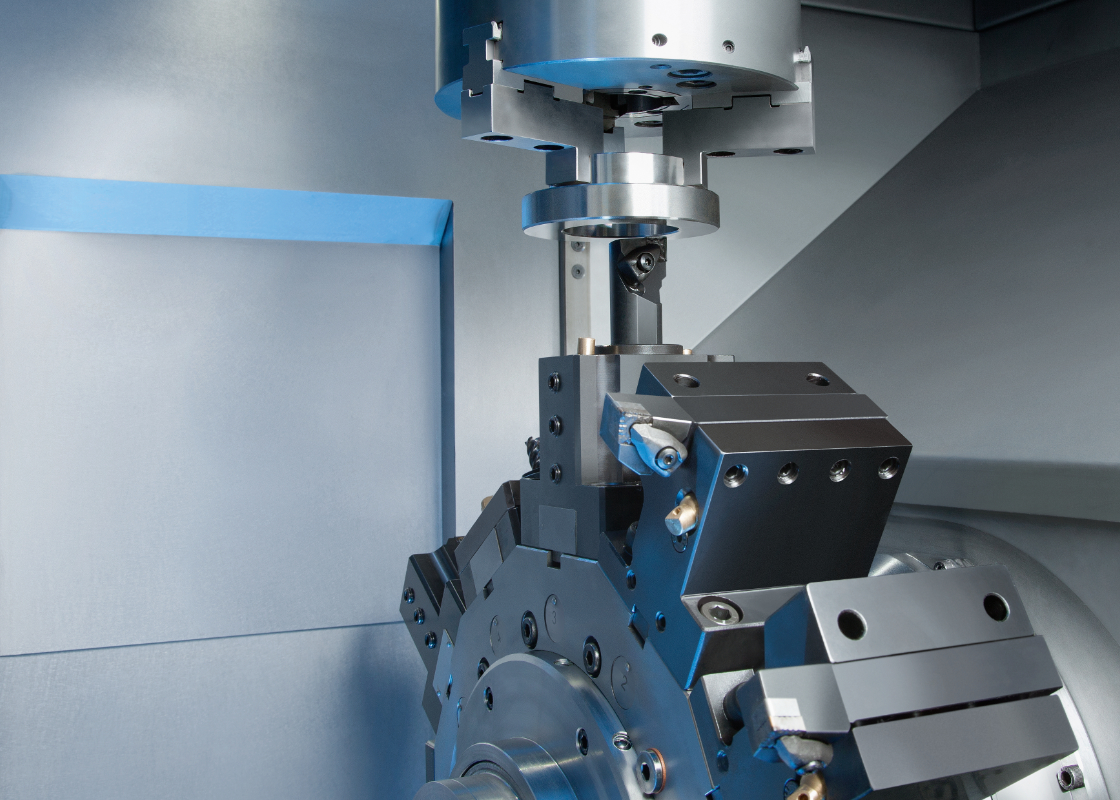

The advantages of the VSC 500 vertical lathe become particularly obvious in the machining of large workpieces, especially when such components not only have to be turned, but also drilled/bored, countersunk, reamed and threads, milled, with keyways or other features added. For such requirements the VSC 500 production machine offers complete-machining in a single setup.

Large Workpieces Efficiently Machined on the Automated VSC 500 Lathe

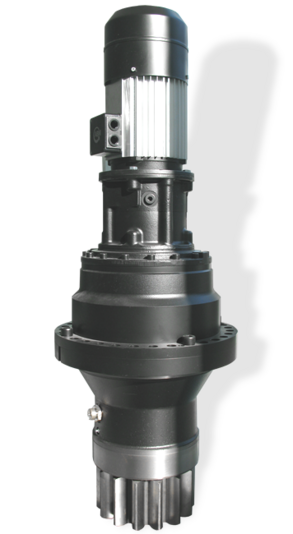

The VSC 500 features an exceptionally robust construction and features a main drive with a power rating of up to 71 kW and a max torque of 750 Nm. Very compact as well, the lathe features a length of just 4 m and a width of just 1.96 m, creating a floor space requirement (without auxiliary equipment) of just under 8 m².

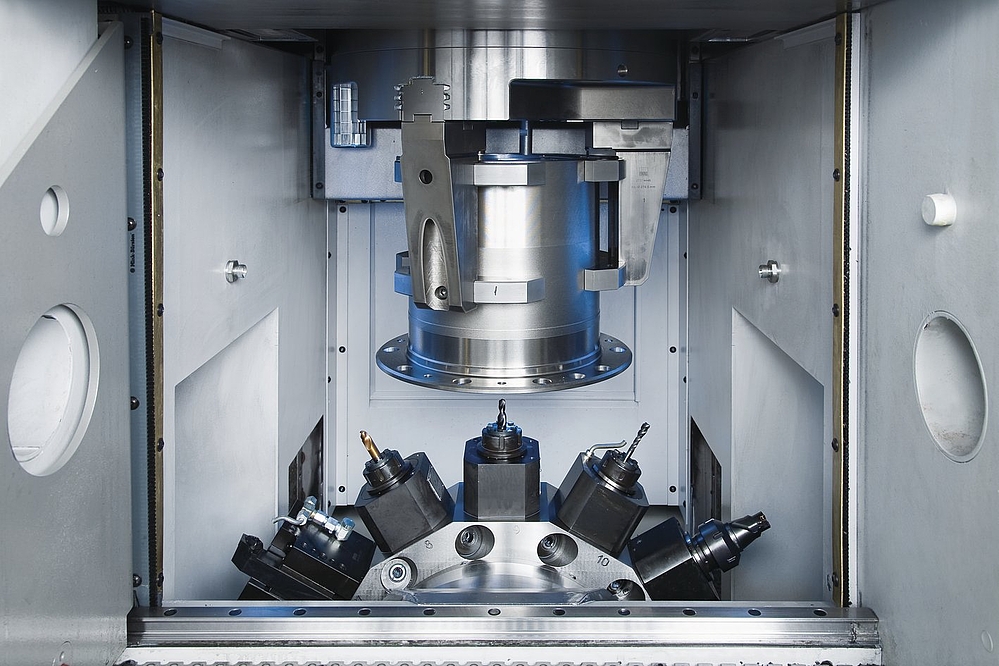

The front wall of the machine features the permanently fixed, and therefore very sturdy, 12-station turret for stationary turning and driven drilling / milling tools.

Advantages VSC 500

- Every machine is a production cell that utilizes its pick-up spindle to load itself

- Short machining travel times and short workhandling times

- Multifunctional production tool: turning, drilling, milling, grinding and other processes

- The workpiece travels while the tooling systems remain stationary

- Ideal chip flow conditions because the tools are located below the workpiece

- The work spindle with a hydro-static guideway in Z-axis (optional) ensures outstanding component quality and a high tool life for soft and hard machining operations

- All accuracy defining machine assemblies are fluid-cooled

- Safe, wear resistant, maintenance-free machining area envelope

- Dry machining is easy with the VSC as the work spindle and tools are ideally positioned for the process

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Drilling is one of the oldest production methods and has been used by humans since the Stone Age.

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Manufacturing lines

Complete Manufacturing Lines or Automation Systems from EMAG

Technical Data

Workpiece dia., max.

500 mm

19.5 in

Workpiece length, max.

200 mm

8 in

Chuck dia., max.

500 mm

19.5 in

| Workpiece dia., max. |

mm

in |

500

19.5 |

| Workpiece length, max. |

mm

in |

200

8 |

| Chuck dia., max. |

mm

in |

500

19.5 |