Coupling Sleeve Machining Centers

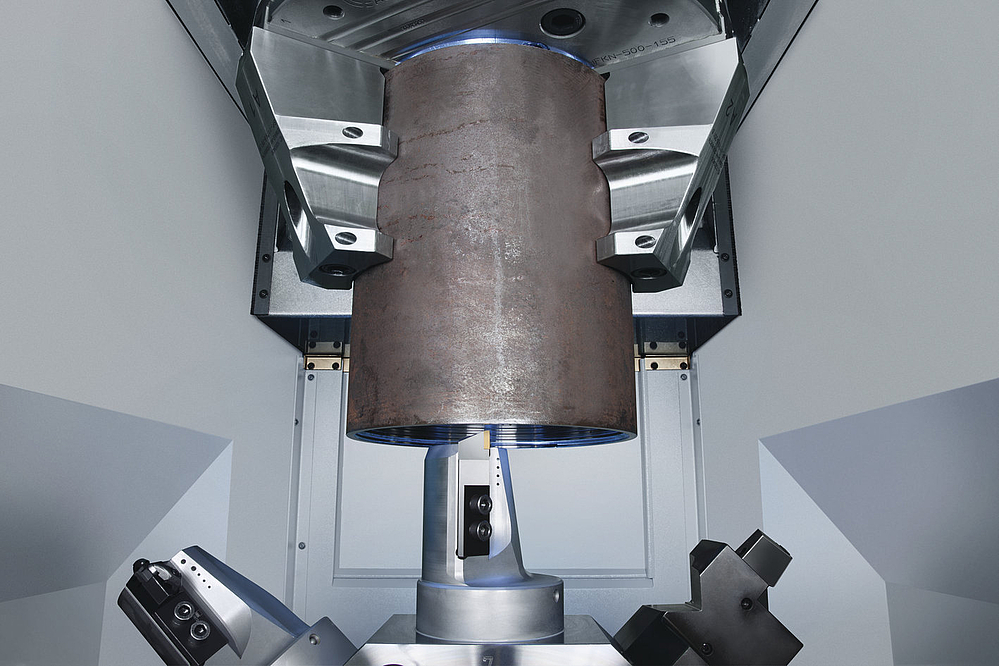

VSC 500 (Couplings)

- Chuck dia., max.: 500 mm | 19.5 in

- Nominal diameter: Inch 6 ⅝ – 13 ⅜

- X-axis travel: 1,000 mm | 39.5 in

Manufacture Every Thread Type on the VSC 500

Complete machine couplings with a nominal diameter (pipe size) of 6 5/8” – 13 3/8” on the VSC 500 vertical pick-up turning machine.

Precision Coupling Production – Machining of Couplings and Tool Joints

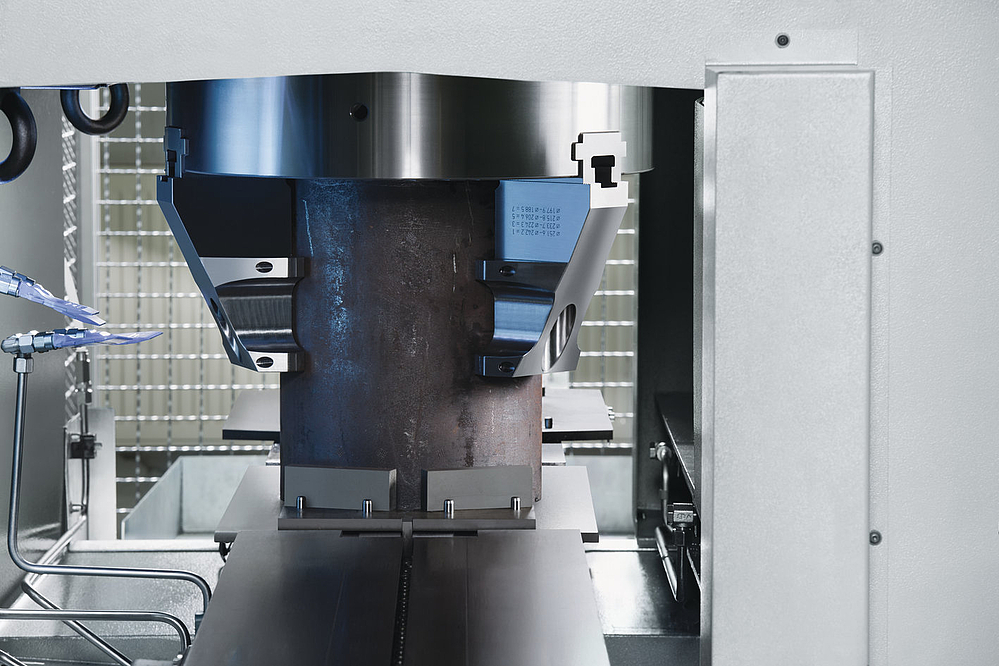

With the VSC 500 turning machine, it is possible to cut all types of threads - including API and GOST standards, which are critical in the oilfield industry. To achieve the highest quality, our VSC turning machine are all designed with a robust machine base made of MINERALIT® polymer concrete.

Flexible Workpiece Flow Reduces Footprint and Costs

The pick-up spindle ensures that the turning machines of the VSC series load themselves. Whether the workpiece is loaded or unloaded from the left or the right, the direction of the workpiece flow – and thus the position of the turning machines in the production line – is customizable. Advantages: the footprint is smaller and link-up costs are considerably lower. Integration into manufacturing systems is guaranteed by the availability of a variety of automation components.

Advantages VSC 500 (Couplings)

- Every machine is a production cell that utilizes its pick-up spindle to load itself

- Short machining travel times and equally short workhandling times

- The workpiece travels while the tooling systems remain stationary

- Ideal chip flow conditions wherethe tools are located below the workpiece

- The work spindle with hydro-static guideway in Z-axis (optional) ensures outstanding component quality and a high tool life for soft and hard machining operations

- All accuracy defining machine assemblies are fluid-cooled

- Safe, wear resistant, maintenance free machining area envelope

- Dry machining is easy with the VSC, because the work spindle and tools are perfectly positioned

Technical Data

Chuck dia., max.

500 mm

19.5 in

Nominal diameter

6 ⅝ – 13 ⅜ Inch

X-axis travel

1,000 mm

39.5 in

| Chuck dia., max. |

mm

in |

500

19.5 |

| Nominal diameter | Inch | 6 ⅝ – 13 ⅜ |

| X-axis travel |

mm

in |

1,000

39.5 |