Big Parts Modular VM

VM 9

- Workpiece dia., max.: 400 mm | 15.5 in

- Workpiece length, max.: 350 mm | 14 in

- Chuck dia., max.: 450 mm | 17.5 in

VM 9 Vertical Turning Center for the Manufacture of Large Components

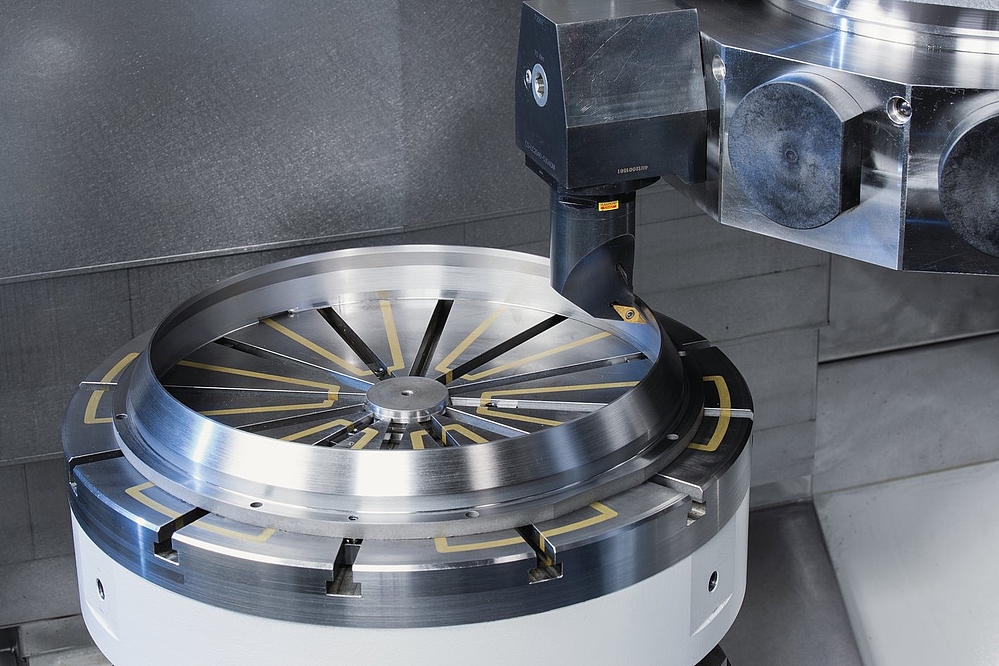

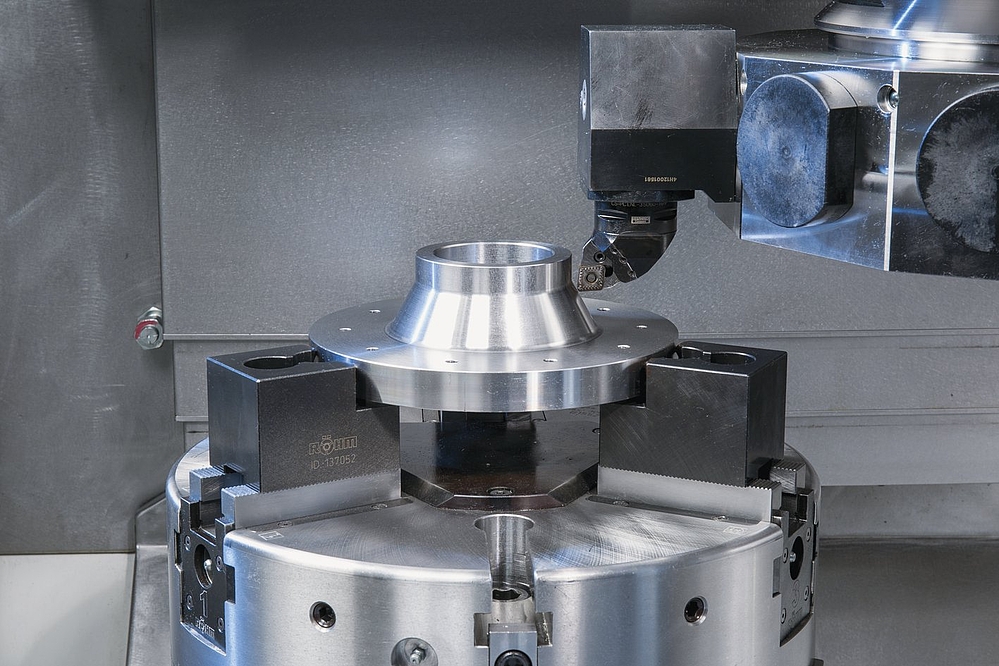

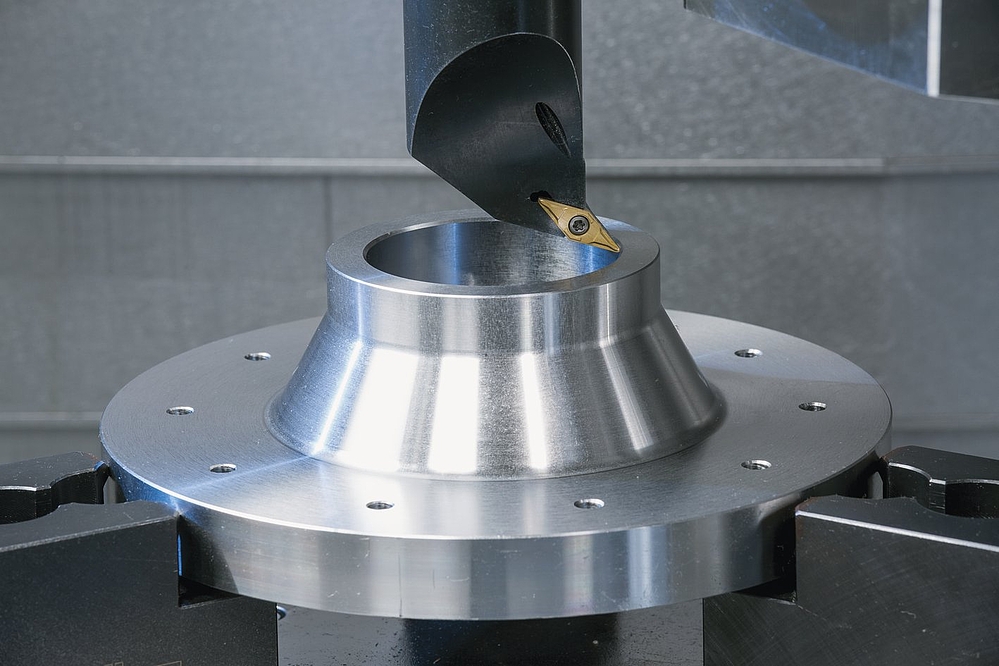

With the new VM 9 vertical turning center, EMAG has introduced a platform that covers a broad spectrum of applications thanks to the combined turning, milling and drilling technologies and intelligent machine design. The highly accessible machining area and workpiece spindle fitted at the bottom ensure short tooling times and maximum flexibility in the production of large components.

The VM 9 CNC Turning Center Machines Large Chucked Components up to 400 mm in Diameter

The heavy-duty foundation of the VM 9 Vertical Turning Center is made of a MINERALIT® polymer concrete column. The particularly good damping properties of Mineralit®, combined with the compound slide with the X- and Z-axes ensure excellent machining quality, high speed processes and short idle times. The main spindle provides the necessary power with a 83 kW rating and a torque of 990 Nm.

Depending on the desired interface (BMT or VDI), the tool turret features eight or twelve tool positions, which can also be equipped with driven tools to carry out drilling operations, for example. The integrated probe ensures process reliability and guarantees consistently high workpiece quality (first part = OK part).

Ergonomic maintenance and loading

But the VM 9 turning center does not just deliver excellent machining quality. The ergonomic design of the machines is perfect evidence of the decades of experience EMAG has with vertical turning machines. Both the machining area and all maintenance components are easy to access. This is is a major advantage for customers who have to cnc machine many different workpieces or various part families.

With the VM 9 vertical lathe, EMAG offers a new cnc machine system for chucked parts suited to the production of a wide variety of workpieces in many different manufacturing scenarios thanks to its flexibility. Whether components for trucks, construction and agricultural machines or for mechanical and plant engineering, the VM 9 turning center is ideal for practically every sector. The excellent accessibility to the machining area makes the machines an all-round solution for turned parts.

Advantages VM 9

- Maximum productivity with highly dynamic axes for short idle times and quick machining processes

- Simple Handling with all service units easy to reach

- Maximum performance from short workpiece transport distances

- High surface accuracy: Axis monitoring by rotary, indirect absolute encoders. All axes with an optional, fully encapsulated linear glass scale

- Ideal for heavy-duty cnc machining with a generously dimensioned main spindle, maintenance-free spindle motors and rigid guideways

- Very high workpiece service lives because the machine body made of MINERALIT® has 6 to 8 times better damping properties than gray cast iron

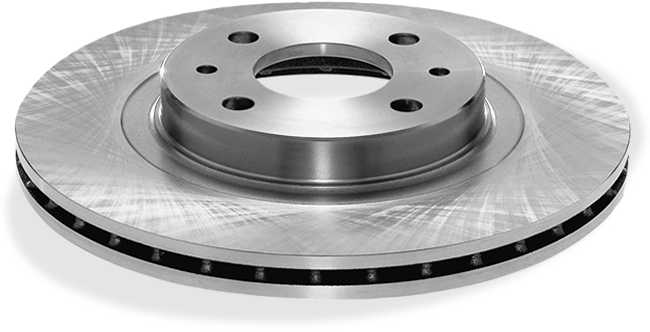

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technical Data

Workpiece dia., max.

400 mm

15.5 in

Workpiece length, max.

350 mm

14 in

Chuck dia., max.

450 mm

17.5 in

| Workpiece dia., max. |

mm

in |

400

15.5 |

| Workpiece length, max. |

mm

in |

350

14 |

| Chuck dia., max. |

mm

in |

450

17.5 |