Multi-Spindle Automatics

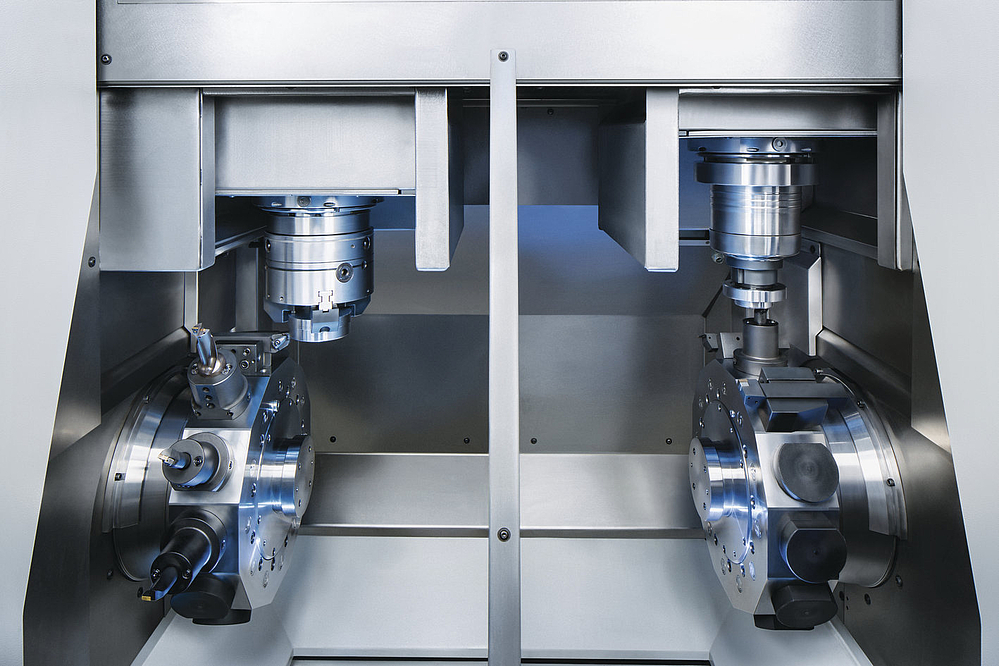

VL 3 DUO

- Workpiece dia., max.: 150 mm | 6 in

- Workpiece length, max.: 110 mm | 4.5 in

- Chuck dia., max.: 210 mm | 8.5 in

Modular Multi-Spindle Machine with Two Work Areas for Vertical CNC Turning

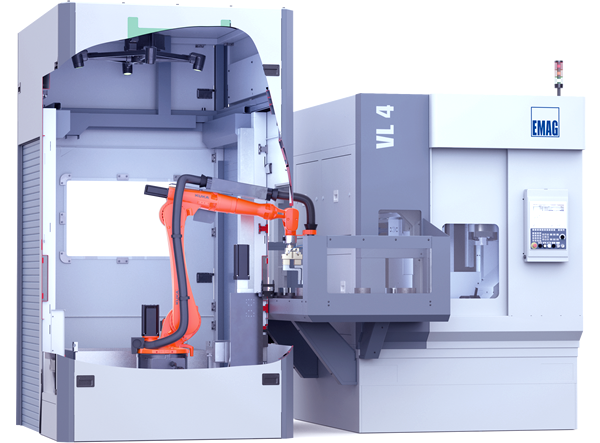

The EMAG VL 3 DUO CNC Machine, an efficient twin-spindle machine solution for chucked parts up to 150 mm in diameter, expands the product portfolio of the extremely successful VL series.

VL 3 DUO – Multi-Spindle Machines for High-Productive Manufacturing of Chucked Parts

The VL 3 DUO turning machines combine the technological developments of recent years, including pick-up automation and the TrackMotion automation system, to the modular basic design of the cnc machine – and creates an extremely efficient production system offering maximum productivity with minimal space requirements.

Like every EMAG modular turning machine, the VL 3 DUO multi-spindle machines are equipped with its own parts storage unit and a pick-up spindle for each work area.

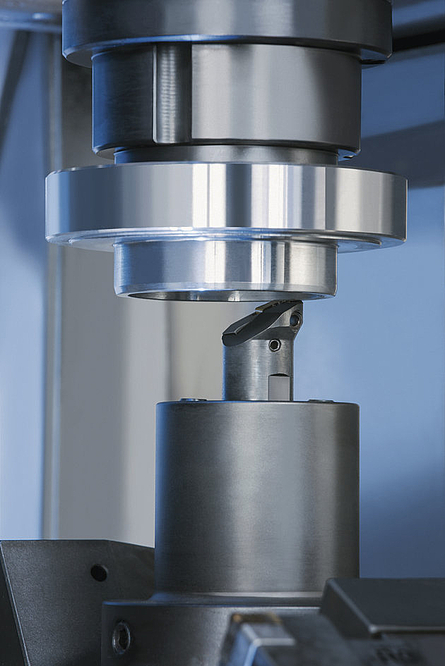

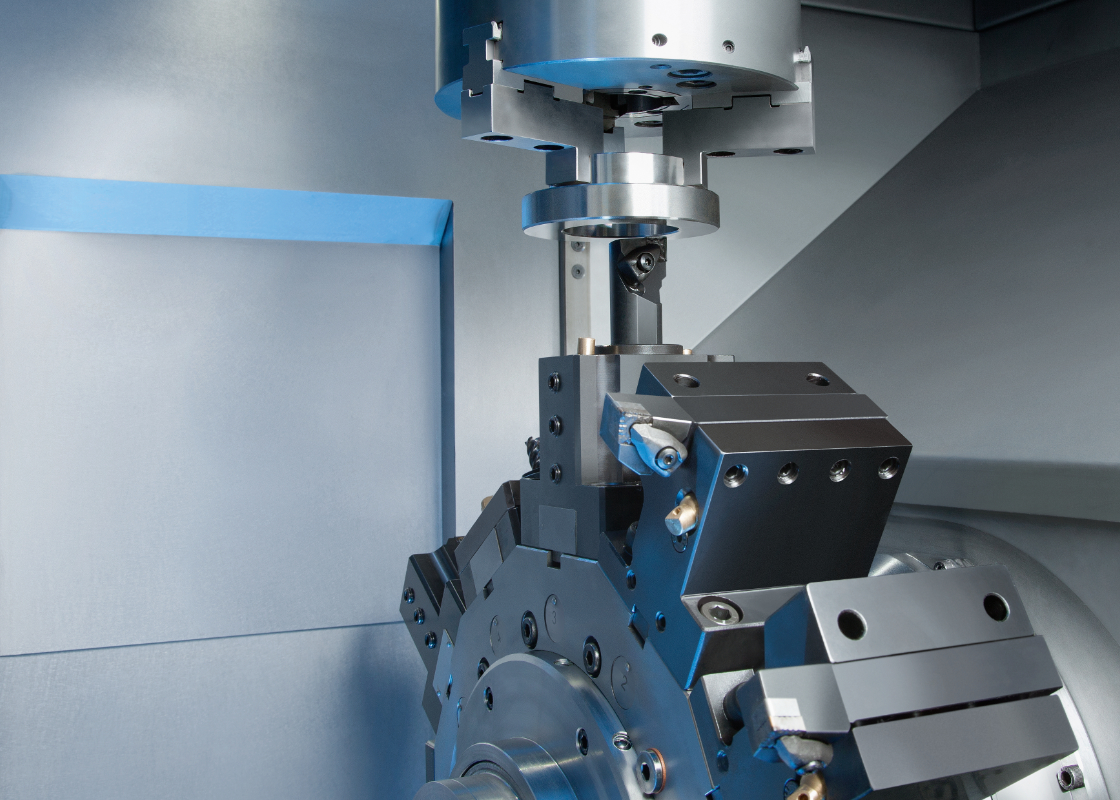

The work areas are mirror images of each other, but each has their own working spindle. With output of up to 17.9 kW and torque up to 144 Nm, these spindles have the power for fast and precise cnc machining. Each work area features a tool turret with 12 tool positions, which can be loaded with driven tools as well as non-rotating lathe tools.

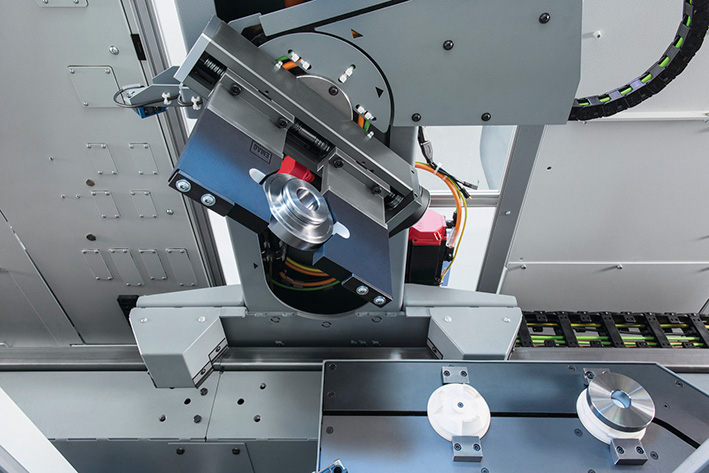

TrackMotion – Modern Parts Management in the Production Process

The EMAG TrackMotion automation system is an option on any VL 3 DUO turning lathe. This automation system consists of three central components: the track, the TransLift NC gripper moving along the track, and the storage unit for raw parts. The entire system is very compact and runs directly behind the work areas of the VL 3 DUO multi spindle machine. With the TrackMotion system, the individual workpiece is always the main focus. During each transport operation, only one workpiece is moved, which provides essential advantages for parts management. The increased mobility of the TransLift, including a Z-axis, makes it possible to use stacker pallets on the parts storage unit, allowing the stacking of raw and finished parts in a very small space. The TransLift unit also functions as the turnover station between the two machining operations. The TrackMotion automation system offers everything required for compact manufacturing on the VL 3 DUO turning machine: a spacious parts storage unit for up to 400 parts, as well as quick, and flexible parts transportation system between the separate machining stations.

Highlights of VL 3 DUO Multi-Spindle Machines:

- Two separate work areas for OP 10 and OP 20. Each work area is equipped with a high-performance pick-up spindle and a turret with up to 12 tool positions.

- The TrackMotion automation system doesn't just rapidly transport parts between the parts storage unit and the work areas, but also flips the parts over between OP 10 and OP 20

- The compact layout ensures maximum productivity in a very small footprint. The machine design also allows for easy access to all work areas, which minimizes set up times.

EDNA IOT-READY EX-WORKS: Get started with data-optimized production with VL series

Using data analysis, unnecessary downtimes – due to component wear or, in the worst case, due to the failure of a machine – can be reduced or even avoided entirely. Productivity increases of over 10% are the rule here. To make entering the world of data-optimized production as easy as possible for our customers, all the machines of the VL Series now come standard in an IoT-ready state. This means that data analysis on the machines can be started virtually immediately.

Advantages VL 3 DUO

- Compact design of multi-spindle machine

- Ideal for high-volume production

- OP 10 and OP 20 on a multi-spindle machine

- 12-post tool turret by EMAG

- Easy implementation of production line systems with other EMAG machines

- Fully compatible with TrackMotion automation system

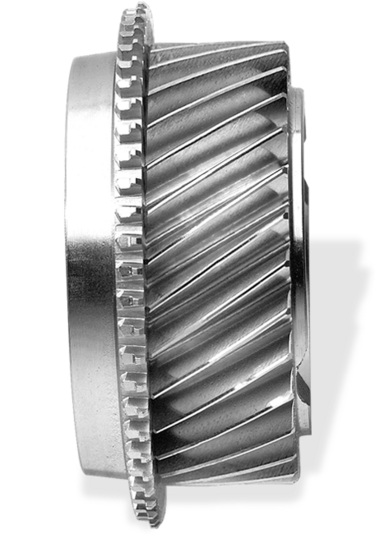

- Ideal for gear parts production

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Manufacturing lines

Complete Manufacturing Lines or Automation Systems from EMAG

Technical Data

Workpiece dia., max.

150 mm

6 in

Workpiece length, max.

110 mm

4.5 in

Chuck dia., max.

210 mm

8.5 in

| Workpiece dia., max. |

mm

in |

150

6 |

| Workpiece length, max. |

mm

in |

110

4.5 |

| Chuck dia., max. |

mm

in |

210

8.5 |

| X-axis travel |

mm

in |

505

20 |

| Y-axis travel (optional) |

mm

in |

±

30

± 1 |