Customized Turning Machine Solutions for your Production

EMAG offers three machine series that are perfectly tailored to a wide range of manufacturing requirements: Classic, Modular and Customized. From economical entry-level solutions to highly specialized systems, EMAG can help you find the optimal solution for your production.

Classic machines

The efficient entry into precision manufacturing

Classic machines combine maximum efficiency with the high quality you expect from EMAG. These machines focus on the essentials and offer an optimized range of functions for typical machining requirements. The base machine is purchased from selected partners and equipped by EMAG with proven process and machining technology, such as chucks and tools. You benefit from EMAG‘s worldwide service network and fast spare parts supply – the ideal choice for cost-efficient production without compromising on reliability.

Modular machines

Customized flexibility

The modular machines, such as the VL series, expand the range to include flexible manufacturing solutions. These machines and system solutions are characterized by a modular design and can be adapted to your specific requirements using a wide range of options. They combine high productivity with outstanding adaptability – ideal for companies with more specific requirements.

Customized machines

Maximum individuality

The customized machines, which include the VLC and VSC series, for example, represent tailor-made cutting-edge technology. Each machine is designed exactly according to customer requirements and is particularly suitable for highly complex processes that require maximum precision and specialization. These solutions offer the greatest possible flexibility for implementing individual production concepts.

Modular VL

Integrated Precision – The VL Series

The modular VL pick-up turning machines are space-saving vertical turning centers with an integrated automation system. Maximize performance and achieve the lowest possible unit cost with these turning machines. Available in a variety of versions, the VL series vertical turning centers allow for the production of workpieces ranging from 10 mm to 400 mm (0.4 in to 16 in) in diameter.

Modular VLCustomized VLC

Custom Manufacturing Solutions Based on VLC Series CNC Turning Centers

The VLC series CNC turning centers offer a wide range of technology modules, and can be customized for specific machining requirements. Turning tools, milling spindles, as well as, multi-spindle drill head modules are available.

Customized VLCModular VM

VM 9 vertical turning center: high-performance turning machine for large chucked components

The VM 9 turning machine from EMAG combines turning, milling and drilling for maximum flexibility. With 83 kW of power, it machines chucked components up to 400 mm in diameter. The base body made of Mineralit® ensures optimum damping and precision. A turret with up to twelve positions enables versatile applications.

VM 9Customized VSC

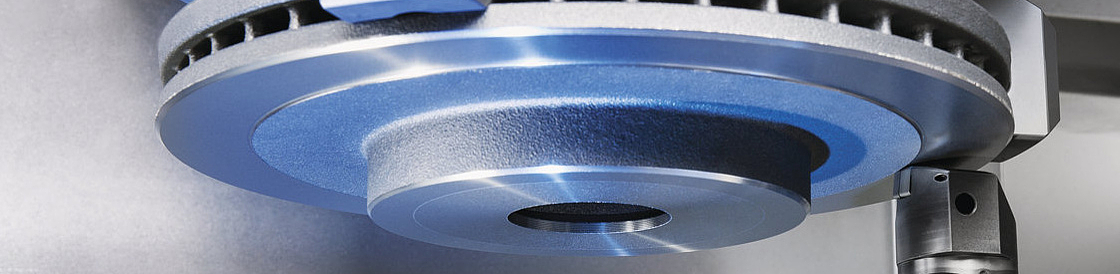

VSC series: Precision turning machine for versatile applications

The VSC series offers a standardized machine concept for lathes with a workpiece dia. of up to 500 mm. With an overhead inverted work spindle and tools working from below, optimum chip fall is made possible. In addition, the stable and low-vibration design of the turning machines ensures high surface finishes and tool life.

Customized VSC

Multi-spindle automatic(s)

Multi-spindle lathes for the highest productivity level in production

Modern lathes are key components in industrial production. Vertical multi-spindle lathes achieve maximum efficiency in the machining of precision workpieces. The compact lathes are characterized by high performance and flexibility. Innovative technologies such as pick-up automation optimize the production process.

Shaft machining Modular VT

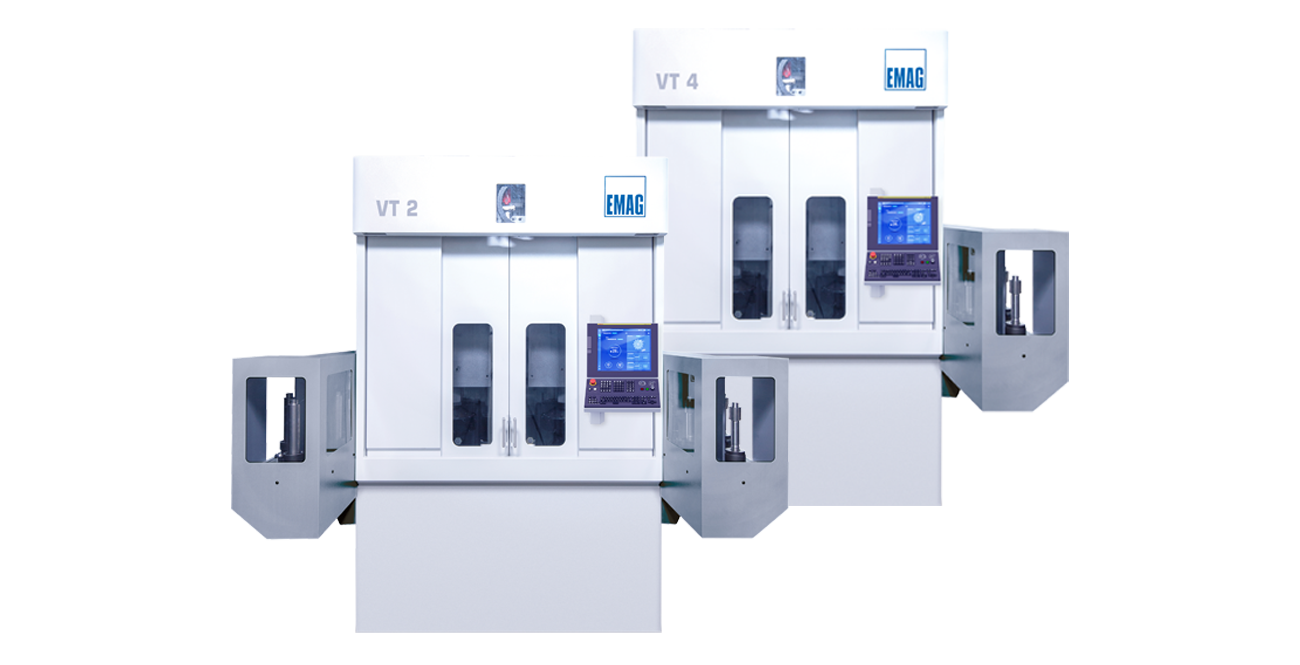

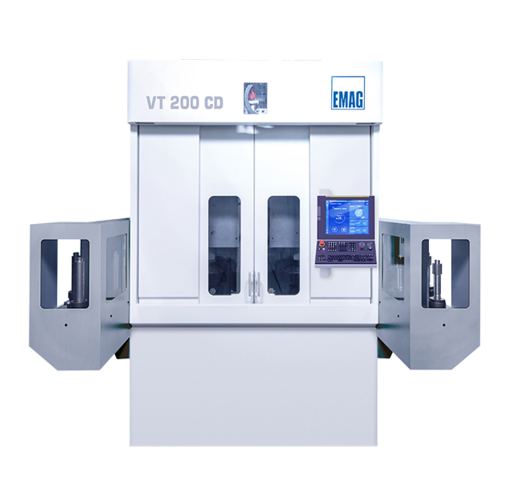

VT series lathes: Efficient shaft production with maximum performance

The VT series lathes offer maximum efficiency in shaft production. With fast machining processes and short loading and unloading times, they guarantee high quantities. The VT 2 and VT 4 models enable precision 4-axis machining for demanding cutting tasks in shaft production.

Shaft machining Modular VTShaft machining Customized VTC

Shaft machining according to customer specifications with VTC lathes

VTC lathes are individual and highly efficient solutions for shaft machining. These vertical turning centers enable complete-machining in a single setup. With integrated automation and powerful spindles, they guarantee short cycle times and high precision.

Shaft machining Customized VTCVertical Turning Centers – An Overview

(29) machines found