External Cylindrical Grinders

HG 204

- Workpiece dia., max.: 200 mm | 8 in

- Workpiece length, max.: 400 mm | 15.5 in

- X-axis travel: 360 mm | 14 in

High-Precision Cylindrical Grinding on the Horizontal Cylindrical Grinder HG 204

Quality requirements for, in particular, ground components are increasing all the time; whilst the integrity of the serial cylindrical grinding process also remains an important criterion. Other main objectives in production planning are the use of short, flexible manufacturing processes. Resetting times must be cut to prevent unit costs from accelerating despite ever greater component diversity and consequently shrinking batch sizes. Furthermore, the variation in batch sizes calls for different automation concepts.

The cylindrical grinder HG 204 is designed for use in manufacturing systems. Here it is where customizing gains its special importance. Access to a large selection of technologies and machining modules ensures that these cylindrical grinders can be equipped to suit individual machining applications. The integrated loader allows for multiple machines to be linked up to form a manufacturing system, or for the machine to be incorporated into existing production lines.

The Cylindrical Grinder HG 204 – a Grinding System that Meets High-Quality Requirements

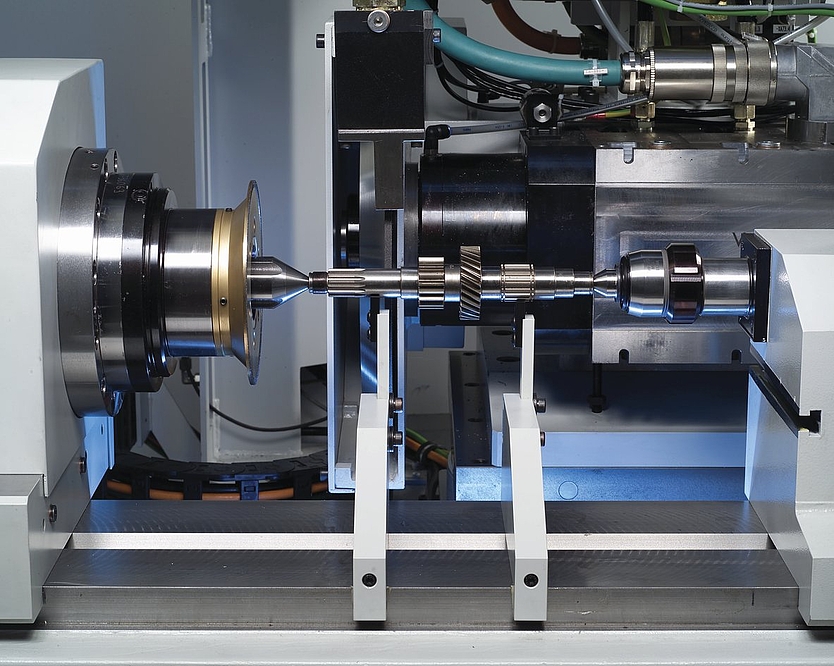

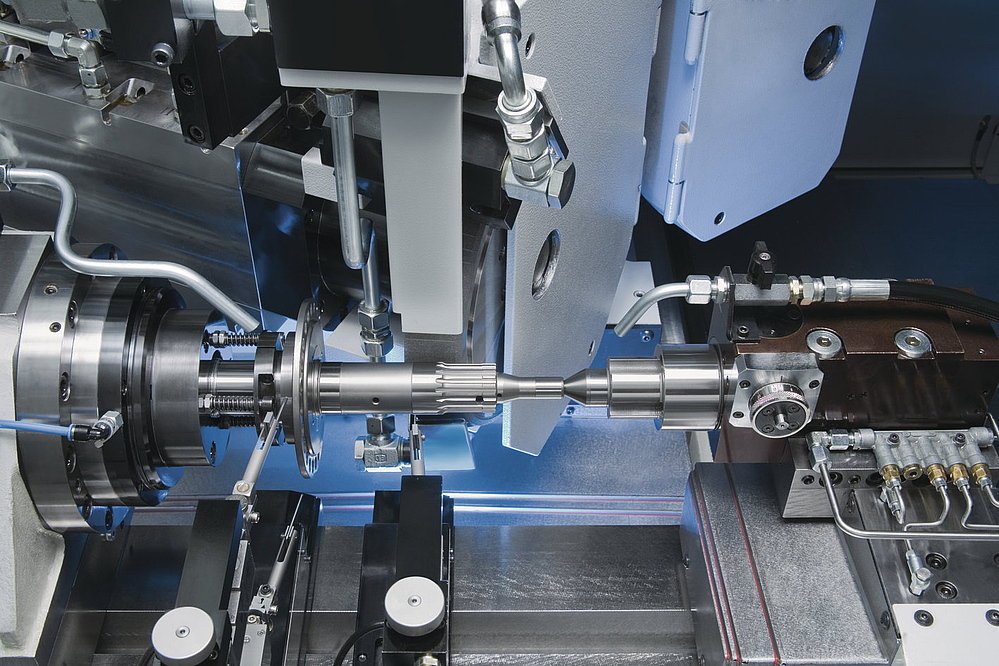

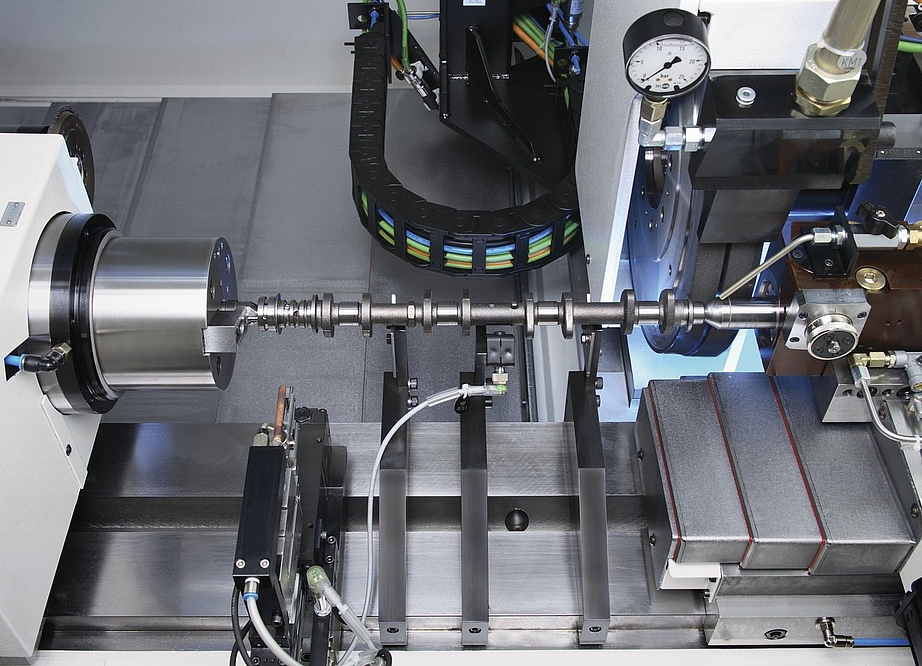

The HG 204 is a cylindrical grinder for the external and internal grinding of medium to large component batches. The HG 204 cylindrical grinder accommodates shafts with a nominal grinding length of up to 400 mm (16 in). The modular design of the cylindrical grinder allows for a number of different machine specifications to perfectly meet individual machining requirements:

- Corundum or CBN grinding wheels

- B-axis with two spindles for external grinding wheels with a max diameter of 500 mm (20 in)

- B-axis with a single spindle for external grinding wheels with a max diameter of 500 mm (20 in), plus two internal grinding spindles

- B-axis with three spindles for external grinding wheels with a max diameter of 400 mm (16 in)

- Work headstock with motor spindle, or work headstock with belt-driven spindle

- Slide-mounted tailstock

- In-process measuring attachment

- Dressing attachment for CBN and corundum grinding wheels

- Touch-recognition for grinding and dressing

- Automatic balancing unit

- Workpiece driver

- Various sizes of chucks and steadies

- Automated loading hatch for linkup with an automatic loading and unloading device

Advantages HG 204

- A high-powered wheel drive shortens machining times

- A contact and crash recognition and wheel balancing system monitors the grinding process

- An in-process gauging control checks O/Ds and the longitudinal position on shoulders

- Operator and setter menus simplify handling

- High-precision, sturdy linear roller guiderails in all axes guarantee the longevity of the machine

- Absolute measuring systems (linear glass scales) in all axes ensure highest machining accuracy

- An NC tailstock with large stroke makes for easy resetting

- Short idle times lead to high productivity levels

- An operator-friendly workpiece error correction system automatically rectifies dimensional errors

- Large doors give optimal access, reducing the distance between operator and workpiece

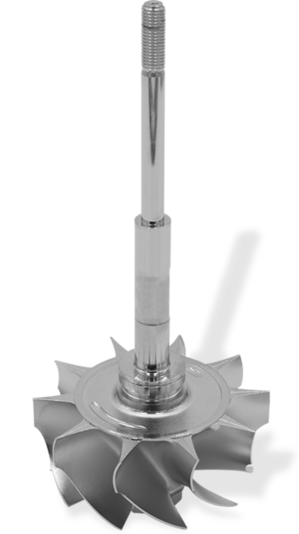

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Finding the right balance between flexibility and productivity is challenge of designing machines for cylindrical grinding.

This demand is met with…

Grinding, besides drilling, is one of the best known chip removal production methods because it is also frequently used during daily activities.

Technical Data

Workpiece dia., max.

200 mm

8 in

Workpiece length, max.

400 mm

15.5 in

X-axis travel

360 mm

14 in

| Workpiece dia., max. |

mm

in |

200

8 |

| Workpiece length, max. |

mm

in |

400

15.5 |