Electrochemical Machining for Manufacturing

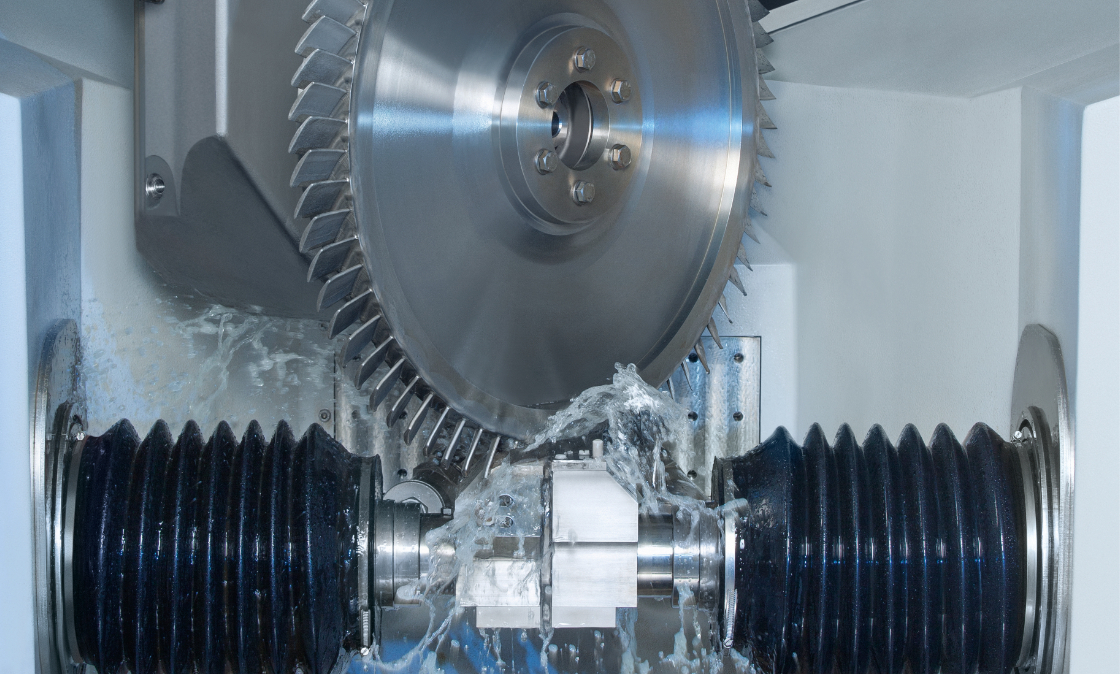

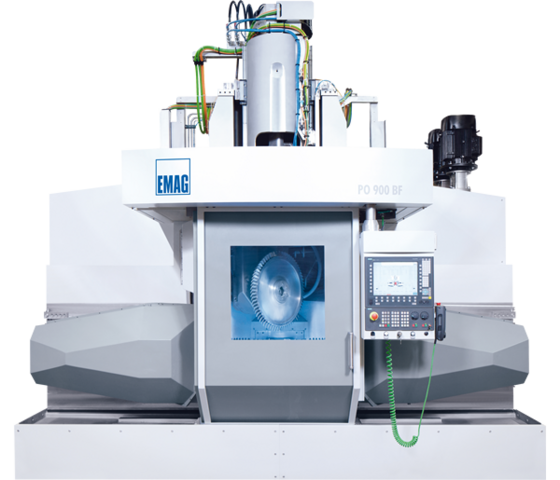

EMAG ECM provides electrochemical machining (ECM) technology and systems for the

production of extremely hard materials and residue-free production of strategic workpieces.

Significant productivity gains can be achieved with machines for the production of engine

parts, such as blisks.

Overview ECM / PECM Machines

(5) machines found